The Berlin Senate is supporting the research projects at the new Werner-von-Siemens Centre for Industry and Science (WvSC) in the Siemensstadt with a total sum of around 30 million euros. In May 2020, the first research project looking into innovative manufacturig methods for electric drives was already approved with 10 million euros. Now, the partners of the other two research projects can also start their work at the WvSC. Over the next few years, up to 160 researchers there will be working on new methods for the production and maintenance of large turbines used in central power generation.

The approval of the funding is an important investment in Berlin's new Siemensstadt as an innovation location. "In these projects, companies and research institutions are working hand in hand on the issues of the future," says Ramona Pop, Berlin's Senator for Economic Affairs. “They create a technology pool that has great potential for applications in other industries. This underlines the radiance of this new future location for the industrial development of Berlin."

The Centre was started in Berlin in 2018 to enable research institutions to work together with corporations and start-ups on the technologies of the future. „Each of the three ongoing projects should be a showcase for structural changes in production technology. Together, we prove that Berlin, research and technology belong together“, says Erik Wiegard, Managing Director Werner-von-Siemens Centre. „We promote science and education here, and we bring together a variety of partners who work at the open heart of production.“

In addition to Siemens, the Technische Universität Berlin (TU Berlin), the Fraunhofer-Gesellschaft and the Federal Institute for Materials Research and Testing (BAM), a number of smaller innovative companies and start-ups based in Berlin conduct research on each of the three projects. The partners are not working in isolated research laboratories, but will come together spatially and at eye level at the WvSC instead.

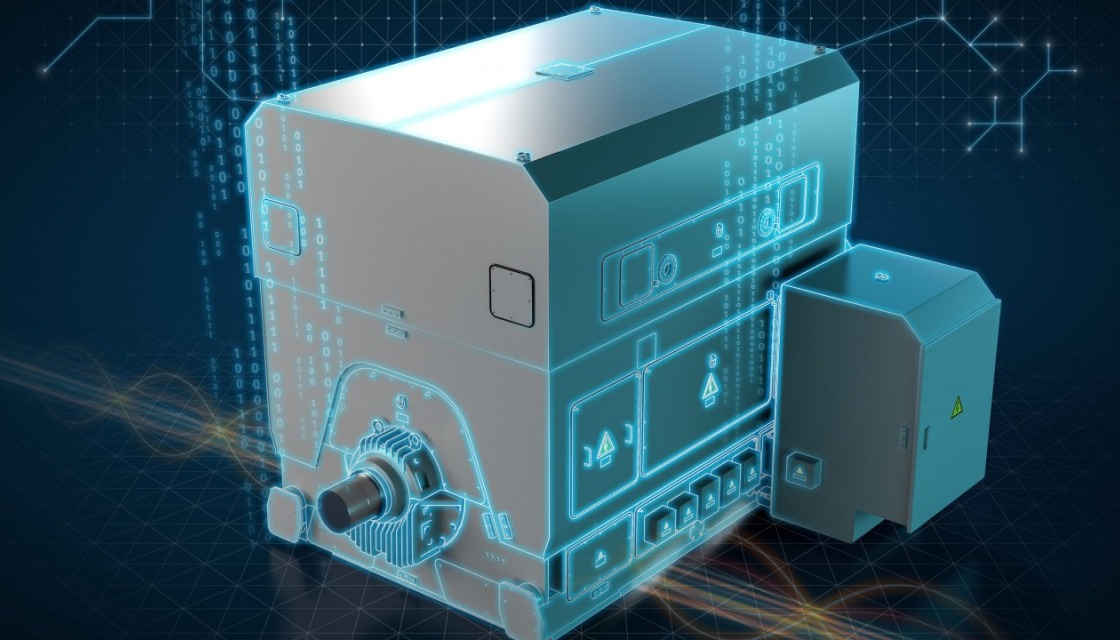

In the first approved future project "Electric Drives", up to 80 researchers from science and industry are addressing the following questions: How can electric drives be manufactured in a more resource-efficient way with a fully digitized and automated production chain? Can components for electric drives also be produced using 3D printing? How can a digital twin guarantee 100% availability of the electric drive at the customer's site? “We will completely rethink the electric drive in the next few years - from the materials to additive manufacturing to the efficient use of highly available online data," explains Siemens engineer Friederike Richter, who leads the "Electric drives" project together with her colleague Frank Seibicke.

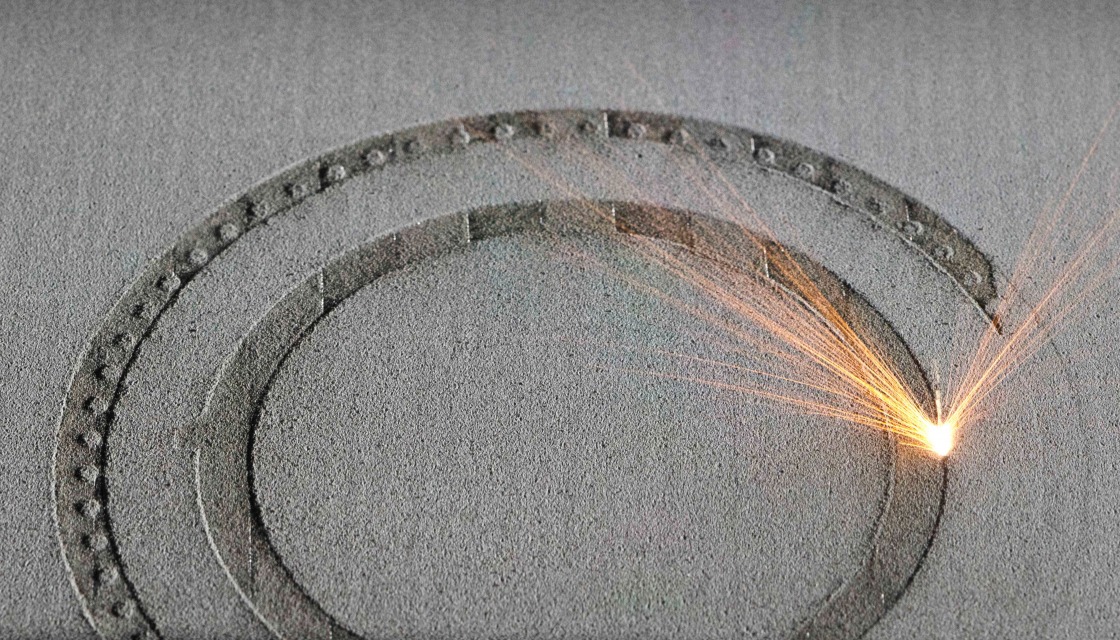

With more than nine million euros, the Senate is supporting the project that explores new production methods for high-temperature components of large gas turbines. "These components are decisive for the efficiency and performance of a turbine," explains Siemens project manager Cynthia Wirth. At the WvSC, 60 employees from eight partners are looking at how these components can be technologically improved and thus become more environmentally friendly. The research work uses the future technologies of additive manufacturing, digital solutions and new materials. It is also important that the research results are to be transferred to related areas, such as aerospace.

A total of eleven partners have joined forces for the project that investigates new approaches to the maintenance of large gas turbines. Over the next few years, up to 100 employees will work on the next generation repair shop for gas turbine blades. The aim is not just to repair the gas turbine blades in the traditional way, but to modernize them with product and process innovations. "To do this, we are researching new technologies such as additive manufacturing, simulation tools for new materials, and digitalization technologies such as the digital twin in order to combine them with standardized repairs," explains Siemens project manager Daniel Koch. The Berlin Senate is funding this project with over ten million euros.

However, the WvSC will not remain with the three projects. Further projects in the areas of the mobility and energy transition are being planned. Would you like to know more about the WvSC and the Berlin research projects? Then follow this link: